A number of months ago there was some initial hype around an individual (Keith Wakeham) that’s building a power meter and documenting the progress in weekly blog posts (though lately more frequent). The current prototypes of his power meter are focused on measuring left/right power within the crank itself. Ironically, he noted in some very early posts way back last summer that he actually had applied to work at Quarq. He just unveiled the name of the company – Accuity – in a recent post.

While the project has merit, what I think is almost more interesting is actually to see a product slowly being put together bit by bit. Not only the weekly progress, but the decisions that have to be made along the way are being highlighted. And there’s a lot of decisions to be made. From technical hardware decisions like chipsets, to software decisions to licensing decisions to fluffy things like markets and target audiences. And that’s just the decision making – which has nothing to do with the actual hands-on designing/engineering, testing, troubleshooting, manufacturing, selling or supporting.

For example, in his most recent post he notes the decisions around ANT+ versus Bluetooth Smart, which I thought was interesting in terms of the detail he listed:

“While I might pick up a BTLE sensor tag from TI [Texas Instruments], I have no ambition to pursue BTLE at this time. Cost mainly. ANT+ will require FCC + $1500 membership + $750 device registration / testing. BTLE requires $22500. I am not joking. I became a BTLE adopter and I can barely understand the documentation and only have the vaguest ideas how it works compared with ANT+. Right now that’s a learning curve I am not willing to accept. If Accuity gets off the ground, has people test some prototypes, then I’ll reconsider.”

I don’t have enough clarity to both sides of the camp to be able to state with 100% certainty that the above is accurate, as I know there have been some changes around Bluetooth Smart lately. The one thing I’ve learned with talking to both organizations and companies working with them is that there are many loops and holes where one can dive through. But, it’s the landscape that hobbyists turned entrepreneurs and eventually turned product-selling business face. Of course, this is true of any industry.

For those interested in my commentary on the above scenario (which is probably about three of you, including Keith) – is that the answer to which protocol question is: ‘Both.’ The way to go is the dual Bluetooth Smart and ANT+ implementation like Stages have done with their Stages Power Meter. This is effectively covering both bases, and gives them (and by extension, end users) complete flexibility when it comes to head units. Folks can go traditional ANT+ like a Garmin/CycleOps/Timex head unit, or they can go cell-phone based apps that support the specification. I really think that any company that’s developing power meters for introduction into the market beyond this summer and isn’t doing this, is already putting themselves behind in the game. There are some dual-chipset challenges today with this area companies are waiting on, in theory these are planned to be resolved in Q2 CY2013, however, I have low confidence in those dates being hit at this point (they’ve been continually delayed). This delay is impacting many companies today and their ability to get dual-protocol products out (actually, it’s impacting almost every company I talk to lately).

One of things I talked about in yesterday’s podcast with the IMTalk folks is that it’s not about getting solutions like Keith’s to 95%. Getting to that point is – all things considered – the easy part. The challenging part is getting that last 5% to work, and more importantly, to work consistently. It’s this last 5% (or even 1-2%) that challenges even the biggest companies. Garmin’s Vector being probably the most perfect example of that. In some cases, that last 1-2% may be in the form of software related issues (for example, where I saw the Stages PM in the January timeframe), and for others, it may be in the form of manufacturing focused issues (for example, where Garmin’s Vector’s issues primarily sit). Even then, upon release companies in the power meter field still have issues. Take Polar, they recalled all their units last spring. While they only had a small number of units out in consumers hands, they were nonetheless recalled to get updated. (Preemptive ‘Where is Vector’ question, most recent answer can be found here.)

Of course, over time most of these technical and production challenges can be solved. But the timeframe to solve them can literally take years. In talking with Keith, he’s been poking at it on and off for a few years (he opened the doors on his prototype work late last summer). Most PM companies spend about 2-3 years working on designs and prototypes until the point of an actual production unit in consumers hands that someone paid for. This is the major reason I generally recommend folks not wait for whatever new-fangled power meter that’s “almost on the market”. There’s a lot of new-fangled power meters that are in perpetual almost on the market state.

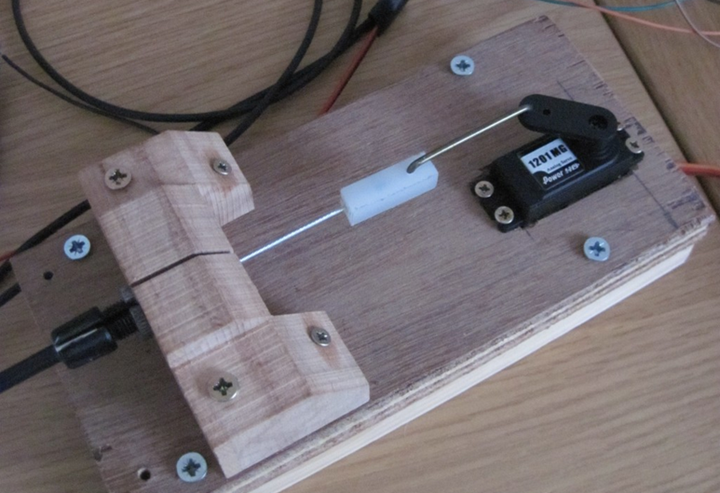

Along the same line as what Keith is doing with his power meter, another man out of the UK is doing on the erg trainer front (resistance controlled trainer).

His goal is to develop a £50 resistance controlled component (electric) that can attach to an existing trainer (i.e. perhaps attached to a $100 trainer), allowing one to control the resistance of the trainer remotely. Just like a CompuTrainer, except about $1,600 cheaper. This is pretty cool in that even the cheapest units in this realm start at about $800-$900 these days.

Now his approach is a bit more homebrew than Keith’s power meter approach. Both have end-states as opensource in terms of guidance, but the trainer will realistically be the only one that the average Joe can probably put together.

In fact, you see below the use of remote control airplane servos as part of the control unit. I expect in time you’ll probably see more polish around the implementation. Like most engineering implementations, things start off looking a bit backwater before they move up to 5th Avenue polish levels. But that’s what makes DIY cool.

Like the power meter blog, the trainer blog is updated weekly with tidbits of his journey along the way. In it are tidbits of the design choices he’s made. Unlike the power meter blog, his goal isn’t to produce a sellable finished product, but rather something you can cobble together yourself. Thus, some of his design aspects are more homely than Keith’s. Take for example this section:

“It soon became clear that sweating over my laptop or dev board, trying to press buttons while training was going to end badly, so I needed a way to more easily enter lap markers and manually change gradient while on the bike. A rummage through the drawer of “things that may come in useful one day” turned up a spare remote from an old fan heater, which was quickly hacked up to provide a wired remote for some up/down, lap, and stop buttons.”

Yup, a fan heater. But, again, that’s what’s cool about DIY – pulling together the pieces. In time I suspect that fan heater remote control will end up being something slightly more repeatable that’s easily bought. For example, Part Number 123ABC off of RadioShack.com or Amazon that provides similar functionality for a couple dollars and doesn’t require you taking apart your household appliances. Mostly because I know The Girl would kill me if I tried to take apart our heater to build something for a trainer. Actually, just another trainer alone would probably get me in a similar end-state.

The point of this post was twofold. One, for all the geeks out there that find this interesting, and two, to give a better understanding of where companies really start out from in the sports tech world. Over the next month or two I’ll also be visiting some companies at the opposite end of this segment, and will show you how they’re building products. From design to engineering to testing and support. The same product development cycles exist in companies large and small, it’s just some use a spare heater controller, and others have dedicated injection mold facilities in China and Taiwan to spit out anything a computer can render.

Thanks for reading!

FOUND THIS POST USEFUL? SUPPORT THE SITE!

Hopefully, you found this post useful. The website is really a labor of love, so please consider becoming a DC RAINMAKER Supporter. This gets you an ad-free experience, and access to our (mostly) bi-monthly behind-the-scenes video series of “Shed Talkin’”.

Support DCRainMaker - Shop on Amazon

Otherwise, perhaps consider using the below link if shopping on Amazon. As an Amazon Associate, I earn from qualifying purchases. It doesn’t cost you anything extra, but your purchases help support this website a lot. It could simply be buying toilet paper, or this pizza oven we use and love.

Do you think there is a market for power meters that still have the “5% problem”, but are a lot cheaper? Now one of the cheapest on the market I think is the Power2max, for “only” €1.000. Quarq and SRM are a lot more expensive at €3-4.000!!!

So say there would be a power meter at give or take 3-400 euros (price of a decent sportswatch/mobile phone) with occasional spikes/dropouts and maybe the possibility to smooth this out manually afterwards in the software, would people buy it? Seeing it is still less than half the price of a “(really) good one”

It depends on where the 5% is. If it’s a problem with data and random drops, then no, I think such a product is limited. If the 5% issue is related to breakage, then no. If however, the 5% problem is related to questionable accuracy, then potentially. And if the 5% is related to a product being fiddly, then the answer is yes.

We see that for example with the iBike units. Some of these units are priced considerably lower than other power meters, but have quirks that keep most buyers away (be it accuracy or implementation).

That said, I think we’ll start seeing a turn in the market starting either later this year, or next spring – from a pricing standpoint. Quite simply, there’s just going to be too many companies in the market with similar (accurate) products that the only way to differentiate will realistically be price (assuming customer service/etc… are equal). This is because there’s a number of non-public companies that are working on PM’s today, no less than five off to the top of my head.

Do you allready have any real life experience with the iBike? I found a couple of blogposts about it, but not an in depth like with the other power meters nor can I find it in the PMoverview.

Yes, I tried one of the units about 2 years ago. I found it finicky. I know lots of folks have good experiences with them, but I also hear about a number of folks that have similar experiences to me. They’ve offered units for review, but at the moment I’m pretty backlogged.

Hi, I’m the guy with the ‘BudgetTrainer’ build log. Thanks for the link – had quite a shock when I saw the jump in site visits today ;)

Am finding it a fascinating build, was surprisingly easy (and cheap!) to get to a point where basic computer control worked well enough for me to use it for all my trainer workouts. But as you point out, it is an ongoing process of refinements, my end goal is to make something that can be relatively easily built and adapted to different trainers.

Jon, I’ve just caught up on the development on the erg trainer front (resistance controlled trainer).

As a former avionics techno-geek I thought I’d raise a potential issue I see with the use of a strong electromagnet due to hysteresis and remanance (Information link: link to electronics-tutorials.ws).

I haven’t had to use electromagnet theory in over a decade so can’t offer any development advice, but hopefully you have already taken this into consideration or are able to make use of this info.

Thanks Thor, that’s a really useful link.

The thought had already crossed my mind, just due to observing some residual magnetism left in the core after removing the current in my early experiments. I have no idea what measurable impact it will have yet.

You’ve also prompted me to enable comments on the build blog. I had been meaning to for a while, as I’m sure there are loads of things I could learn from readers.

Regards,

Jon

Awesome post! This blog just keeps getting better and better – my inner geek thanks you!

+1 from Thor R! I really enjoyed reading this post. Great blog.

Thanks Ray – that was a very interesting read. I’m off to check out the links.

I read this article. I think you put lot of efforts in this article. thanks for sharing with us.electronics devices

The world of sports is full of small companies that are trying to solve big problems. They’re trying to invent new ways to improve performance or invent new tools for coaches and athletes. It’s a tough business because it’s hard to build a business on ideas that don’t work yet, especially when you don’t have any money.