Heads up – Massive Sports Tech Holiday Deals List is Live!!! The Garmin Fenix 8 is $250 off (even the Fenix 8 Pro is $100 off!), the Apple Watch Ultra 3 is on sale, the Garmin inReach Mini 2 is $249, the GoPro Hero 13 Black, DJI NEO, and a ton of other brands/deals, including Wahoo, Oura, Whoop, Polar, Samsung, Google, and more than 100 sports tech deals here!

I’m DC RAINMAKER…

I swim, bike and run. Then, I come here and write about my adventures. It’s as simple as that. Most of the time. If you’re new around these parts, here’s the long version of my story.

You'll support the site, and get ad-free DCR! Plus, you'll be more awesome. Click above for all the details. Oh, and you can sign-up for the newsletter here!

Here’s how to save!

Wanna save some cash and support the site? These companies help support the site! With Backcountry.com or Competitive Cyclist with either the coupon code DCRAINMAKER for first time users saving 15% on applicable products.

You can also pick-up tons of gear at REI via these links, which is a long-time supporter as well:Alternatively, for everything else on the planet, simply buy your goods from Amazon via the link below and I get a tiny bit back as an Amazon Associate. No cost to you, easy as pie!

You can use the above link for any Amazon country and it (should) automatically redirect to your local Amazon site.

While I don't partner with many companies, there's a few that I love, and support the site. Full details!

Want to compare the features of each product, down to the nitty-gritty? No problem, the product comparison data is constantly updated with new products and new features added to old products!

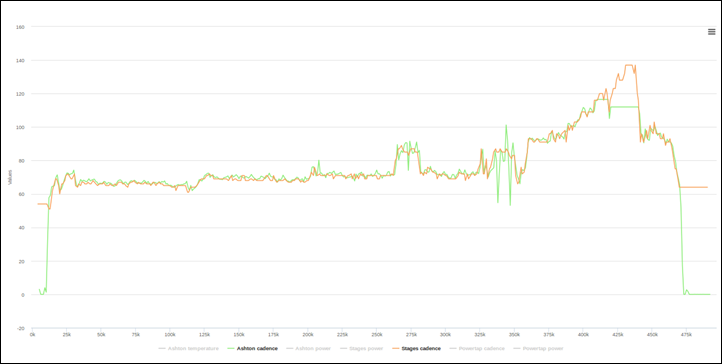

Wanna create comparison chart graphs just like I do for GPS, heart rate, power meters and more? No problem, here's the platform I use - you can too!

Think my written reviews are deep? You should check out my videos. I take things to a whole new level of interactive depth!

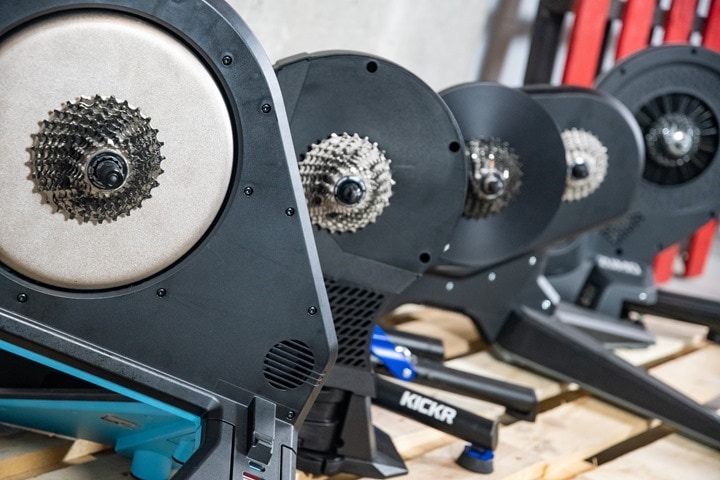

Smart Trainers Buyers Guide: Looking at a smart trainer this winter? I cover all the units to buy (and avoid) for indoor training. The good, the bad, and the ugly.

-

Check out my weekly podcast - with DesFit, which is packed with both gadget and non-gadget goodness!

Get all your awesome DC Rainmaker gear here!

FAQ’s

I have built an extensive list of my most frequently asked questions. Below are the most popular.

- Do you have a privacy policy posted?

- Why haven’t you yet released a review for XYZ product you mentioned months ago?

- Will you test our product before release?

- Are you willing to review or test beta products?

- Which trainer should I buy?

- Which GPS watch should I buy?

- I’m headed to Paris – what do you recommend for training or sightseeing?

- I’m headed to Washington DC – what do you recommend for training?

- I’m from out of the country and will be visiting the US, what’s the best triathlon shop in city XYZ?

- What kind of camera do you use?

-

5 Easy Steps To The Site

In Depth Product Reviews

You probably stumbled upon here looking for a review of a sports gadget. If you’re trying to decide which unit to buy – check out my in-depth reviews section. Some reviews are over 60 pages long when printed out, with hundreds of photos! I aim to leave no stone unturned.

Read My Sports Gadget Recommendations.

Here’s my most recent GPS watch guide here, and cycling GPS computers here. Plus there are smart trainers here, all in these guides cover almost every category of sports gadgets out there. Looking for the equipment I use day-to-day? I also just put together my complete ‘Gear I Use’ equipment list, from swim to bike to run and everything in between (plus a few extra things). And to compliment that, here’s The Girl’s (my wife’s) list. Enjoy, and thanks for stopping by!

Have some fun in the travel section.

I travel a fair bit, both for work and for fun. Here’s a bunch of random trip reports and daily trip-logs that I’ve put together and posted. I’ve sorted it all by world geography, in an attempt to make it easy to figure out where I’ve been.

My Photography Gear: The Cameras/Drones/Action Cams I Use Daily

The most common question I receive outside of the “what’s the best GPS watch for me” variant, are photography-esq based. So in efforts to combat the amount of emails I need to sort through on a daily basis, I’ve complied this “My Photography Gear” post for your curious minds (including drones & action cams!)! It’s a nice break from the day-to-day sports-tech talk, and I hope you get something out of it!

The Swim/Bike/Run Gear I Use List

Many readers stumble into my website in search of information on the latest and greatest sports tech products. But at the end of the day, you might just be wondering “What does Ray use when not testing new products?”. So here is the most up to date list of products I like and fit the bill for me and my training needs best! DC Rainmaker 2024 swim, bike, run, and general gear list. But wait, are you a female and feel like these things might not apply to you? If that’s the case (but certainly not saying my choices aren’t good for women), and you just want to see a different gear junkies “picks”, check out The Girl’s Gear Guide too.

Interesting. So how come only single sided? Wouldn’t the left side twist the spindle the other way?

Does it need to measure cadence (or do it anyway)?

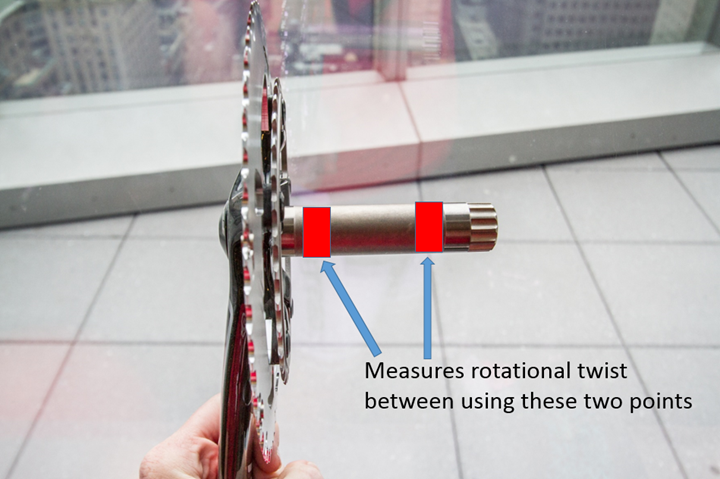

The right (drive side) pedal power goes pedal -> crankarm -> spider -> chainring -> chain

The left pedal power goes pedal -> crankarm -> axle -> spider -> chainring -> chain

The right side doesn’t go through the axle, so any axle-based power meter would essentially measure zero for the right leg.

So this would be drive/right side power, correct? Would it be possible to combine it with a left side option like 4iiii to get two sided power?

Left side power…it’s measuring twist in the axle which originates from the left side.

Interesting/pity that you didn’t test with cleats, as wouldn’t left side upwards “pull” reduce twist on the spindle.? Seems to me there is room for material errors in that scenario

No, it wouldn’t! If you’re applying power in the forward direction (on upstroke or downstroke), you’re twisting the spindle in the same direction.

It doesn’t measure ‘up’ and ‘down’, it measures the torque and the direction of rotation it is applied to. If you pull up on the pedals you are extending that torque through more degrees of rotation & the unit would capture that. What would be really confusing for the unit is if you put it in a fixed gear.

Why would that be confusing for it? When you slow your pedal speed, it would record negative power, which makes complete sense.

A couple of typos:

Oh..and one thing: There are no straight gauges. <===strain

So we decided to go up to the 35th floor of the hotel on a desk outside the fitness center. <===deck

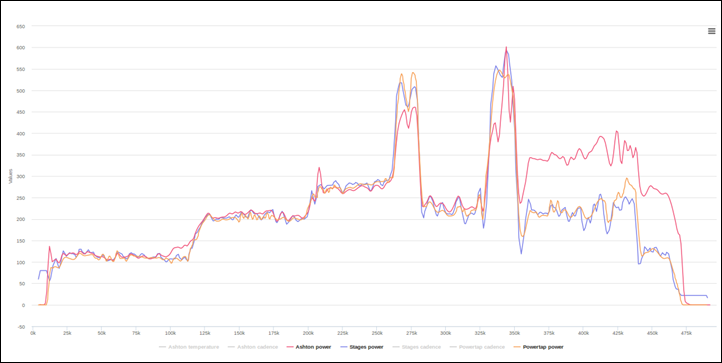

In looking at both differences they believe they’re largely because there’s a tiny bit of sleep going on at high power/cadence levels on the current prototype. <===slip

And one factual error. "Namely that it only measures one-leg (right in this case)" I'm certain it is measuring non-drive side power (left), since that is the only power transmitted through the bottom bracket "axle".

Grr, thanks for the typo corrections!

I’d guess left too (unless sitting on the saddle backwards :-) ).

Next time Ray you should totally set the bike up on a desk on the deck outside the fitness centre as a little inside joke for your regulars

How about battery replacement? That would probably require extracting the PM – or would there be some way to access that.

All in all, a very interesting concept – looking forward to any further updates!

It would be pretty easy to replace the battery, since it would be just popping out the unit (just two screws). Not much different than the work effort on something like a PowerTap or Power2Max. Quarq is probably the easiest as it requires zero screws, but overall most units are just a few minutes of work.

Very clever. It’s essentially a torque tube based system, like a PowerTap, except that the power meter is bearing a small part of the overall torque, rather than all of it.

Questions:

1. Will they be able to maintain accuracy over time & temperature? IF they’re not using strain gauges to measure the deflection, what are they using? Would be interesting to know their expectations on accuracy,

2. Each type of crank will twist a different amount, and the manufacturing variations with each crank vendor’s model mean that each individual specimen will twist a different amount. That means the user will need to calibrate on installation, against a known good reference. I suspect that will not prove user friendly.

3. How is wireless transmission from inside the (metal) bottom bracket going to work? Is there a good enough radio path from there to the head unit? May need an antenna sticking out from the centre of the crank.

Hi flobble, great questions!

1. It will be very accurate, meeting the current standards of direct force power meters, and we are implementing temperature compensation to maintain accuracy. As for the sensor, we’re using robust solid-state components which measure the spindle’s twist.

2. Yup, the user will calibrate on installation. We know that user-friendly installation and calibration is one of the most important aspects of our power meter and we’re fine-tuning a very simple calibration procedure.

3. We’ve successfully tested radio modules down the spindle, but yes, antenna placement is important and we will be doing further extensive testing as we continue the product development.

It’d be awesome if there was some mechanism for saving a calibration! That way if you’re switching bikes often, you don’t have to calibrate every time. Of course, this would only be if testing confirms that calibration is not significantly changed simply by the act of installation.

If it doesn’t use strain gauges, what does it use ? IIRC Ergomo used light (lasers), but that meant it used a lot of battery power (which was in the headunit as it was fully wired)

I can see this attachment method working for FSA cranks or SRAM, but campag (and specialized) spindles attach together in the middle and shimano are only open on one end (before you put the cap on). How do they plan fitting onto those cranks ?

Our first generation power meter is designed for crank spindles that are open at both ends like many FSA and SRAM options. As we’re able to further shrink the form factor in later generations, we think there are some creative ways to make an insert type power meter compatible with most crank designs.

What are they using, if not strain gauges?

Why not use strain gauges – a proven and cheap technology?

Hi Ryan,

We’re using solid-state sensor components which measure the spindle’s twist.

Cost is actually one of the main reasons we decided not to go with strain gauges. Even though our raw sensor components are already somewhat cheaper than strain gauges, it’s manufacturing advantages that really make the difference. There is an interesting BikeRadar Article that looks into this, if you’re interested.

Another advantage of using solid-state components is their robustness, an area where strain gauges sometimes struggle.

As an electrical engineer, this really intrigues me. How much detail can you give without going into trade secret type stuff?

How many sensors are measuring the twist?

If they aren’t measuring strain, are they measuring rotational displacement?

Is it actually measured in a manner similar to a strain gauge (bridge circuit + amplifier + A/D)?

How often are you sampling the torque?

How often are you sampling angular velocity?

The last two will help head off the inevitable questions about using this on non-round chain rings.

Is it QTC material based?

(such as: link to peratech.com )

Or perhaps a MEMS device.

If I were to hazard a guess I’d say a piezoelectric.

This could be the one.

How easy/quick would it be to swap it between bikes?

What is their “thing” that they are going to bring to the table over proven models on the market? Stages & Garmin Vector are pretty easy to install, but this will beat them on price (for now). Competition is great and time will tell I guess.

I’d agree with Flobble below.

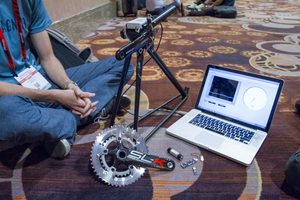

The key/biggest thing (aside from price), is that it’s easy for anyone to install. If you watch the video, you’ll see how silly easy it is. Anyone who can install a water bottle cage can install this. The same (unfortunately) can’t be said for Vector or Stages (for the vast majority of the bike population).

Assuming accuracy, reliability etc end up as required, then I can think of three:

1. Installation and removal with a standard hex key (vs torque wrench) would be good.

2. If the calibration didn’t need to be repeated each time, Bluetooth would allow connectivity with a smartphone app so you could say “you’re now in my TT bike, here’s your calibration” or “you’re now in my road bike, here’s your calibration” or “you’re now in my mountain bike, here’s your calibration”

3. Much greater independence from crank type, pedal type, wheel type. None of the existing solutions can really provide that today.

I’m really excited about all the powermeter competition that seems to be coming. Its something I really want to add to my training, especially since I use a trainer a lot, but the current cost I just can’t justify.

Can there be more than $50 worth of parts in the Stages or 4iiii Precision Power Meters. Seems to me the $100 Price level can’t be too far away ..!!

How about Campagnolo Over-torque and Power-torque?? I believe they have a 1 piece spindle

Good morning, when is there bottom bracket with 2 screws of compression?

Screws of the sensor would replace them?

To everyone who thinks that the drive side doesn’t exert force on the spindle – if that was true, the NDS crank wouldn’t move when you pedalled one-legged.

You are all welcome to experiment, but I’d recommend googling “Newtons Third Law” instead

With the proliferation of one sided power meters there is a new need for possible addition to tracking options in head units to allow for right/left leg imbalances. In my case, I have a Quark on my road bike that I have been using for over a year. It shows that I have a 5% to 10% difference between legs. I have ordered a 4iiii meter for use with my mountain bike which will be installed only on my left crank. So I know that when installed, my mountain bike will probably read low when compared to my road bike.

It would be nice if I could somehow set up my Garmin Edge 810 to adjust my power measurements for when riding the mountain bike to read about 7% high so that it will correlate more closely with my road bike readings. As it is, I do spin classes once or twice a week on bikes that use a left sided Stages manufactured power meter and I have to always do a mental adjustment to the power readings.

The biggest issue here is when all this data goes into Sporttracks Training Load where it is best to have some consistency between different bike power measurements for you overall load tracking to make sense.

This would be a nice update to Garmin bike computers.

Since it is measuring rotational twist wont using clip ins lower the power reading if pulling up on one leg while pushing down on the other?

I think that could be a real issue – I just can’t see how that won’t reduce (or in an extreme case eliminate) spindle twist

It will work just fine. In the same way that any of the left-crank-only designs work just fine. From the pedal spindle to the chainrings, it’s a (mostly) rigid unit. All of it deflects, just in a different way/different amount according to geometry and material.

Plus:

(a) there is good evidence that pulling up on the pedal doesn’t happen much. It’s mostly just ‘unweighting’ to varying degrees. But that doesn’t matter because..

(b) single sided pedal meters assume that pedal action is symmetrical, so any forces from the “lazy” pedal occur apply equally to both sides. If the drive side foot was pulling up, and ‘reducing’ the measurement on the non-drive side, then 180 degrees later, the non-drive side would be pulling up, and this would be measurable, so it can be handled appropriately.

If you accept the assumption of symmetry, it’s really a non-issue.

If anyone is convinced that a single side power meter isn’t good enough because of left/right asymmetry, then they buy one that is dual sided, is in the spider, or is in the wheel. Or learn to pedal in a symmetric way.

If Bill is still around, I’d appreciate some clarification.

The article says the device measures rotational twist. Of what? Of the device? How is the device anchored to the actual drive mechanism of the bike…isn’t slippage a major problem?

If I align my crank arms horizontally, and stand on my pedals (thus not going anywhere), it seems like that will produce maximum twisting of anything mounted in the bottom bracket (one pedal is trying to go fowards, the other backwards).

If I pedal just with the left leg, there is twisting between the left crank arm and the spider, since the chain is making it hard for the spider to turn. It sounds like that twist is what you’re measuring?

What if, as others have pointed out, I pull up with my right leg at the same time? I’m reducing the twist AND putting out more power. It seems like that couldn’t just be ignored.

Never mind, I get it.

The device measures how much _additional_ force your left leg is contributing to the chain ring/spider, beyond what your right leg is doing. If your left leg wants to move the spider faster than the right leg is doing already, you’ll get twist. That means your left leg is applying force to the drivetrain. Assume left and right are equal and now you have total power. Pulling up is handled by the fact that your left leg is contributing power (And twist) on the upstroke and downstroke. Again, assume symmetry and now you have total power for both legs.

Looks like they are going to be a bit late to the market seeing that Rotor just launched something very similar: link to bikeradar.com

Any plans for a review of that?

Ask and you shall receive: link to dcrainmaker.com

Aside from ease of installation, this finaly looks like something that can be easily swapped around between roadbikes and mountainbikes! If so, I want it!

I just checked out the Ashton website and am very impressed that they had recently won several awards (2014 MIT 100K Semi-Finalist, 2014 MIT GFSA Alumni, 2014 MassChallenge Finalist and $50K Gold Award Winner). It could likely be more than a year to get their product to market. Ashton has a lot of hurdles and challenges to get to the next level.

Seeing the third hand in the Video freaked me out :-)

Great write up as usual.

Just wondering if you have any inside updates about product release or availability from Ashton? Their website never seems to change, and I’ve been really excited about this product for… to long now. ?

-Guillermo

Looks like they are out, like Brim Brothers.

No updates for ~2 years and website has been taken down http://www.ashtoninstruments.com